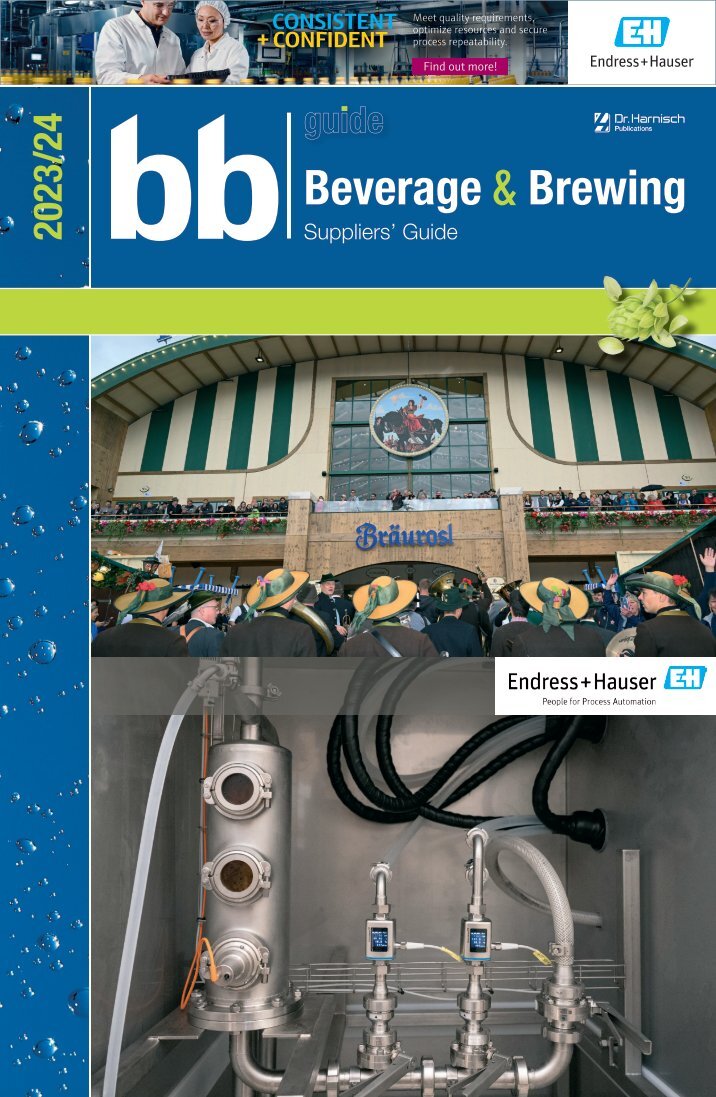

Tapping the first keg in the Bräurosl festival tent on opening day of the 187th Oktoberfest on the Theresienwiese in Munich, 9 September 2022. Image: Hannes Magerstaedt

World premier – first in-tent vacuum insulated piping (VIP) system for festival beer at the Munich Oktoberfest 2022

In 2022, millions of visitors once again visited the Oktoberfest in Munich after a two-year hiatus forced by the corona pandemic. And none of them died of thirst! The Paulaner Brewery Group introduced a world premier this year in the Pschorr Bräurosl beer tent: the first vacuum insulated piping system (VIP) for beer installed directly in the tent at a height of 3.5 meters. The measurement technology for the smooth operation of the beverage supply system, including the non-alcoholic keg dispensers, is from Endress+Hauser.

Paulaner has been using underground ring-based piping since 2010 to supply its Oktoberfest tents with beer. This year the brewery installed a world premier in the Bräurosl tent: the first above-ground vacuum isolated piping for the central beer supply system. The entire system has a modular design that offers the following advantages: weather conditions have no negative impacts and installation/deinstallation times are significantly reduced. The temperature difference is a mere +0.3° C within 24 hours, at an ambient temperature of 30° C and a beer temperature of 0° C. This represents a considerable improvement over the underground piping system. Another centerpiece is the measurement technology from Endress+Hauser. As summed up by brewing engineer Uwe Daebel: “Our recipe for success: we have the innovative ideas and work together with reliable partners like Endress+Hauser to implement them.”

The measurement technology can be found at many points within the Oktoberfest tent:

Bierant for the Oktoberfest beer in the tent*

(*Works according to the artesian principle. Any air or gas present in the VIP system is removed and the beer is distributed to the taps via “pythons”).

An ingenious idea by Uwe Daebel, brewing engineer at the Paulaner Brewing Group! Everyone knows what the word hydrant means and how it functions. According to Wikipedia, a hydrant is an outlet from which water can be tapped. Accordingly, a so-called Bierant © (a portmanteau of the German Bier and hydrant) retrieves the beer from the transfer piping and sends it to the taps. The Bräurosl Oktoberfest tent contains four Bieranten©, each of which is furnished with innovative measurement technology. The Liquicap M FMI51 capacitive level sensor monitors the level and the Picomag electromagnetic flowmeter monitors not only the flow, but also the temperature and conductivity. The combination of these three measurement parameters plays an important role in efficient CIP cleaning of the dispenser technology. The full potential comes to bear first and foremost with the gastronomy technology however, since it has to be cleaned every 14 days at the latest, and then documented with the help of the conductivity measurement value. Where several instruments might be needed for monitoring the parameters, now a single device – the Picomag from Endress+Hauser – takes over this task. The instrument’s compact dimensions are advantageous in tight installation spaces. The Picomag furthermore comes with an integrated IO-Link interface as a standard feature and can be easily integrated into common field bus systems. Cloud connectivity is also simple to establish.

Delivery of the beer via the technology container – the control center of the central beer supply system for the festival tent

Beer transfer takes place via the technology container. The tanker truck is connected to the central supply system on the beer and gas side via hoses. The beer volume is determined with a custody transfer system.

Since the tanker trucks and beer tanks are connected on the gas side (gas pendulum process = equal pressure), a pump is needed to transfer the beer to the tanks (capacity, 3 x 28,000 liters), which are installed on a stainless steel frame approximately 4 meters above the technology container. When the system is in the “festival tent” operating mode, the three tanks simultaneously and continuously feed the transfer piping. From there the beer is fed to the dispenser taps via the four Bieranten©. To compensate for the reduced pressure in the system caused by the falling levels in the tanks, the pressure is regulated and kept constant with CO2 gas, which is monitored by the Deltapilot FMB50 hydrostatic level instrument. The three beer lines to the tanks are equipped with Liquiphant M FTL50H vibration point level switches, which trigger the empty tank notification when the beer is removed from the tanks at the conclusion of the Oktoberfest.

Monitoring the keg beverages

Apart from the festival beer, the tent offers other beverages delivered in kegs. Whether non-alcoholic beer, soft drinks, mineral water, Paulaner Spezi (a mixture of cola and orange soft drink) or Shorle (apple juice mixed with carbonated water), an Endress+Hauser instrument is responsible for monitoring the flow at each tap. The Bräurosl tent thus has 30 Picomag flowmeters with integrated IO-Link interfaces for the keg beverages. The instruments monitor three parameters in this environment as well: flow, temperature and conductivity.

All important information at a glance

How do you reliably maintain a focus on the beverage supply system? It’s easy: either by viewing the display monitor (Maß-o-Meter) in the technology container located on site, or via the comfort of a cloud connection from any location. All Endress+Hauser Picomag instruments are furnished with an IO-Link interface as a standard feature. The current value is continuously transmitted to the IO-Link master and then passed to the cloud. That means at the end of an Oktoberfest day, Paulaner can order the volume of beverages for the next day using the data captured by the instruments – relaxed and worry-free. This ensures no beverage shortages and no thirsty visitors.

But that’s not all. At the end of a large-scale event such as the two-week Oktoberfest, the captured data can be used to carry out a detailed analysis. Optimizing beverage consumption and personnel resources at future events thus becomes child’s play.

The Endress+Hauser Group

Endress+Hauser is a global leader in measurement and automation technology for process and laboratory applications. The family company, headquartered in Reinach, Switzerland, achieved net sales of more than 3.3 billion euros in 2022 with a total workforce of nearly 16,000.

Endress+Hauser devices, solutions and services are at home in many industries. Customers thus use them to gain valuable knowledge from their applications. This enables them to improve their products, work economically and at the same time protect people and the environment.

Endress+Hauser is a reliable partner worldwide. Its own sales companies in more than 50 countries as well as representatives in another 70 countries ensure competent support. Production facilities on four continents manufacture quickly and flexibly to the highest quality standards.

Endress+Hauser was founded in 1953 by Georg H Endress and Ludwig Hauser. Ever since, the company has been pushing ahead with the development and use of innovative technologies, now helping to shape the industry’s digital transformation. 8,700 patents and applications protect the Group’s intellectual property.

For further information, please visit www.endress.com