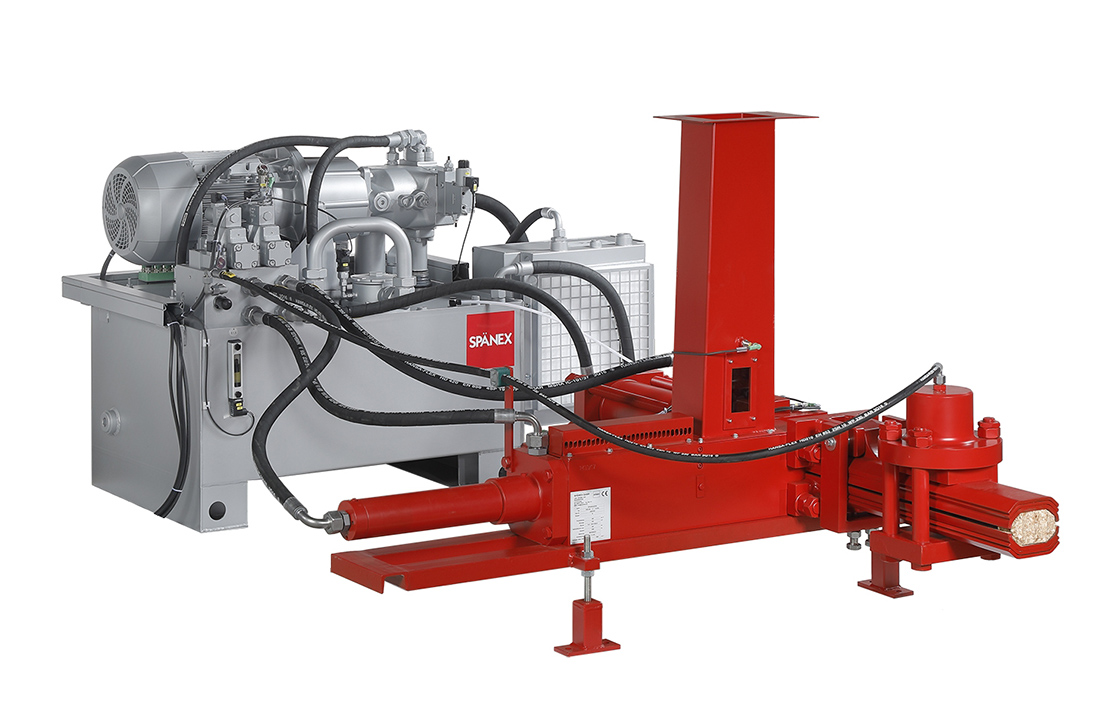

SPÄNEX, the specialist for extraction and briquetting systems, will once again be presenting its innovations and product improvements on the topics of extraction, conveying, filtering, dedusting, briquetting, painting, controlling and shredding in the direct vicinity of the WEINIG Group in Hall 9, Stand No. 305, where an extraction system in live operation with a total air capacity of 50.000 m3/h based on dust extractors is shown, which will be used to extract the woodworking machines exhibited and demonstrated by the WEINIG Group.

SPÄNEX is using this trade fair to show a broad public the new extraction system concept based on dust extractors, which has meanwhile been used many times and proven in practice, in live operation. Two stations, each with two dust extractors, will be set up and operated on the exhibition stand, with each dust extractor providing a maximum air out-put of 10,000 m3/h. Another dust extractor with a maximum air output of 10,000 m3/h will be placed on the WEINIG Group stand, so that the maximum total volume flow is 50,000 m3/h.

The background to this dedusting-based system concept are customer requirements where, due to local conditions, the filter systems cannot be installed outside the buildings as required by the regulations. The tried and tested alternative solution of installing the filter system indoors and equipping it with flame- less pressure relief devices is also not feasible in some cases for structural reasons, so that another solution had to be found. SPÄNEX has therefore developed this system concept on the basis of dust extractors.

All five exhibited dust extractors are operated according to demand. This means that the required volume flow changes depending on the woodworking machines being demonstrated. Practice has shown that this demand-dependent system operation leads to considerable electricity savings compared to conventional system technology.

Briquetting presses are arranged below the three dust removal stations and are started up automatically depending on the amount of chips. The performance spectrum of the machines ranges from 70 to 250 kg/h. Customers can thus also get a picture of the machines’ mode of operation and the excellent briquette quality in live operation.

Due to the great demand, a dust extractor for extracting dust from hand-held machines and manual work stations is exhibited in conjunction with an extraction table, which is characterised by a particularly high suction pressure of up to 10,000 Pa. The dust extractors of this series are equipped as standard with energy-saving motors of quality class IE3 in combination with a frequency converter.

Hall 9, Stand 305